Rapid Decarbonization Potential Of Pune Metropolitan Region (PMR):

Feasibility Report for a Net Carbon Neutral PMR

August 2022

Prepared by the EECC Programme of PIC Headed by Prof. Amitav Mallik, Trustee, PIC

Contributors:

Dr. Gurudas Nulkar, Director, CSD – GIPE, & Advisor, PMR NCN Project, PIC

Mr. Siddharth Bhagwat, Team Leader and Project Manager, PIC

Ms. Shalvi Pawar, Project Associate, PIC

Mr. Prithviraj Lingayat, Research Associate, PIC

About this Report:

This study was being conducted to assess the feasibility of the decarbonization pathway of PMR through a technological and financial lens. The report attempts to identify the priority areas for decarbonization, and the practicality of undertaking steps to decarbonize.

About Pune International Centre (PIC):

Pune International Centre (PIC) is a non-profit think tank which deliberates on issues of national importance. PIC has several verticals, namely Social Innovation, National Security, International Relations, Energy Environment and Climate Change, and Economics.

Disclaimer:

This report is based on an independent analysis. Neither PIC nor BP have any commercial engagements. This study was done for research. The views expressed in this policy brief are those of the contributors/authors and do not necessarily reflect the views and policies of the PIC or the reviewers.

Editorial Team:

Mr. Siddharth Bhagwat, Dr. Gurudas Nulkar, Prof. Amitav Mallik, Ms. Shalvi Pawar and Mr. Prithviraj Lingayat.

Suggested Citation:

Nulkar G; Bhagwat S, Mallik A; Pawar S; Lingayat P. (2022). Feasibility Assessment of Rapid Decarbonization Potential for a Net Carbon Neutral Pune Metropolitan Region, Pune International Centre.

Acknowledgements:

The EECC team at PIC would like to thank Dr. Vijay Kelkar, Vice-president, PIC, for giving us the opportunity to conduct this study with support of BP India for their funding and keen interest in decarbonization of PMR. Throughout this study, we collaborated with multiple consultancies and researchers in Pune to provide their valuable analysis including SeeGreen Solutions team led by Dr. Nitant Mate, VK:e Environmental Services & Sustainability Initiatives team led by Dr. Poorva Keskar, Prakruti Organics team led by Mr. Santosh Lalwani, Pune Knowledge Cluster team led by Ms. Rashmi Urdhwareshe & Dr. Priya Nagaraj, National Chemical Laboratory team led by Dr Magesh Nandagopal, Symbiosis International University Infrastructure Management team led by Dr. Kedar Bhagwat and Dr. Vasundhara Sen, Symbiosis International University Energy and Environment Management team led by Amit Teotia and Vinit Joshi, and Poornam Eco-vision Foundation team led by Dr. Rajesh Manerikar. We would also like to thank other contributors from ProEarth, Sentient Labs KPIT, Ecological Society, Swach, Prayas, Parisar, Prima Plastech, Centre for Environment Education. We would also like to thank the Pune Infosys team for arranging a study visit to their campus.

We would also like to thank the government bodies and officials for their co-operation including Mr. Saurabh Rao, Ms. Poonam Mehta, Ms. Suwarna Ogale from the Pune Divisional Commissioner’s Office; Mr. Vikram Kumar, PMC Commissioner; Dr Rajesh Deshmukh, PCMC Commissioner; Dr Suhas Diwase, PMRDA Commissioner; Ms. Rakshada Rode, PMRDA; Mr. Kunal Khemnar, Additional Commissioner, PMC; Mr. Mangesh Dighe, PMC; Mr. Sanjay Kulkarni, PCMC; Deepali Dhede, PCMC; Sandeep Khot, PCMC; and Sandesh Chavan, PCMC. We would also like to thank officials from MSEDCL, Pune Petroleum Dealers Association, Pune RTO, and Pimpri-Chinchwad RTO. We would also like to thank Ms. Vaishali Patkar and Ms. Aditi Kale from CCP Environmental Foundation for their valuable support and Dr. Prakash Rao from Symbiosis International University for arranging interns to work on the study.

Finally, we would like to thank Mr. Pradeep Bhargava, Dr. Mahesh Zagade for their valuable inputs on the project as Steering Committee Members. We would also like to thank Mr. Prashant Girbane, General Secretary, PIC; Mr. Abhay Vaidya, Director, PIC; EECC researchers Ms. Riya Gandhi, Ms. Preeti Ahluwalia and Mr. Deepak Dhanve, Ms. Kiran Pardeshi, Amrish, Tejas and Mayur from the PIC office.

Prof. Amitav Mallik Head, EECC

Trustee, Pune International Centre

Organizations and Research Team

SeeGreen Solutions LLP, Pune

Dr. Nitant Mate, MD, SeeGreen Solutions; Ms. Avani Hardikar, Research Assistant

National Chemical Laboratory (NCL), Pune

Dr. Magesh Nandagopal, Principal Scientist and Head, Technology Management Group, CSIR-NCL; Dr. Mangesh Vetal, Scientist, Technology Management Group, CSIR-NCL

Dr. Geetanjali Date, Consultant, Pune International Centre

Dr. Prerana Tomke, Senior Project Associate, Technology Management Group, CSIR-NCL; Ms. Namita Upadhyay, Project Associate II, Technology Management Group, CSIR-NCL

Pune Knowledge Cluster (PKC)

Mrs. Rashmi Urdhwareshe, Senior Advisor, PKC; Dr Priya Nagaraj, COO, PKC

Sustainability Initiatives, Pune

Dr. Poorva Keskar, Partner, VK:e, & Trustee, SI (Strategic Head); Ms. Anagha Paranjape-Purohit, Partner, VK:e & Trustee, SI

Ar. Kanchan Sarbhukan-Sidhaye, Sr. Associate, VK:e; Ms. Shivali Waichal, Program Coordinator, SI

Mr. Gaurav Limaye, Environmental Analyst, VK:e; Ar. Sayali Kulkarni, Energy Analyst, VK:e

Symbiosis Centre for Management and Human Resource Development (SCMHRD)

Dr. Kedar Bhagwat, HOD and Faculty (IDM)

Dr. Vasundhara Sen, Faculty, MBA Infrastructure Management; Dr. Rahul Hiremath, Faculty, MBA Infrastructure Management; Mr. Sameer Gujar, Adjunct Faculty (IDM)

Mr. Ankush Kumar Rout, Student, MBA (IDM); Mr. Rishabh Natholia, Student, MBA (IDM); Mr. Sanjay S, Student, MBA (IDM)

Mr. Satadru Chowdhury, Student, MBA (IDM)

Ms. Aakanksha Hajela, Student, MBA Infrastructure Management; Mr. Ayush Deore, Student, MBA Infrastructure Management

Mr. G Suneeth, Student, MBA Infrastructure Management

Mr. Sarvesh Saxena, Student, MBA Infrastructure Management

Symbiosis School of International Business, Pune

Mr. Amit Teotia, MBA Energy and Environment, SIIB; Mr. Vinit Joshi, MBA Energy and Environment, SIIB

Poornam Eco-vision Foundation, Pune

Dr. Rajesh Manerikar, CEO

Ms. Tanvi Chandratre, Project Coordinator; Mrs. Namita Khatavkar, Project Coordinator; Dr. Ashwini Bhole, Research Volunteer

Er. Prasanna Joshi, Research Volunteer; Mrs. Isha Bhate, Research Volunteer; Ms. Protisha Ghosh, Research Intern; Ms. Divya Gujar, Research Intern

Mr. Mahesh Lohakare, Research Intern; Mr. Mrunal Khalde, Research Intern; Ms. Deepti Kale, Research Intern

Ms. Tanaya Thatte, Research Intern

Prakruti Organics and Sustainable Solutions, Pune

Mr. Santosh Lalwani, Director

Ar. Anto Gloren, Research Assistant

Ms. Harshada Nikam, Research Assistant; Ms. Kalyani Bawa, Research Assistant; Ms. Prachi Ramteke, Research Assistant

Mr. Prathmesh Muley, Research Assistant; Mr. Rajat Joshi, Research Assistant

Ms. Saee Ghule, Research Assistant; Mr. Tanay Lalwani, Research Assistant

CCP Environmental Foundation, Pune

Ms Vaishali Patkar, Director; Ms Aditi Kale, Director

PIC EECC Researchers

Ms. Riya Gandhi

Ms. Preeti Ahluwalia

ProEarth Ecosystems, Pune

Mr. Anil Gokarn, Director

Ms. Hamsa Iyer, General Manager

Sentient Labs KPIT, Pune

Mr. Kaustubh Pathak, Tech Lead, Alternative Fuels

Prima Plastech Ltd., Pune

Mr. Likhit Lasaria, CEO

Abbreviations:

| Institutions | |

| CEEW | Council on Energy, Environment and Water |

| CRISIL | Credit Rating Information Services of India Limited |

| CSIR | Council of Scientific & Industrial Research |

| DISCOM | Distribution Companies |

| EESL | Energy Efficiency Services Limited |

| IEX | Indian Energy Exchange Limited |

| MNGL | Maharashtra Natural Gas Limited |

| MPCB | Maharashtra Pollution Control Board |

| MSEDCL | Maharashtra State Electricity Distribution |

| MSME | Micro, Small & Medium Enterprises |

| NASSCOM | The National Association of Software and Service Companies |

| NHAI | National Highways Authority of India |

| NITI | National Institution for Transforming India |

| PMC | Pune Municipal Corporation |

| PMR | Pune Metropolitan Region |

| PMRDA | Pune Metropolitan Region Development Authority |

| PXIL | Power Exchange of India |

| REDD+ | Reducing Emissions from Deforestation and forest Degradation |

| RTO | Regional Transport Office |

| SDA | State Development Authorities |

| SME | Small and mid-size enterprises |

| TMG | Tokyo Municipal Government |

| WRI | World Research Institute |

| Policies/Schemes | |

| NEP | National Electricity Policy |

| SATAT | Sustainable Alternative Towards Affordable Transportation |

| SLNP | Street Lighting National Program |

| UDAY | Ujwal DISCOM Assurance Yojana |

| Technical/Others | |

| CCMS | Central Control and Monitoring System |

| EE | Energy Efficiency |

| RE | Renewable Energy |

| ACS | Average Cost of Service |

| AI/ML | Artificial Intelligence (AI) and Machine Learning (ML) |

| AR4 | Fourth Assessment Report |

| ARR | Aggregate Revenue Realized |

| AT&C | Aggregate Technical & Commercial |

| BAU | Business as Usual |

| BLDC | Brush less Direct Current |

| BMS | Battery Management System |

| BMW | Biomedical Waste |

| C&DW | Construction and Demolition Waste |

| CBG | Compressed biogas |

| CDM | Capital Derivatives Management |

| CPM | Charging Point Manager |

| DAP | Diammonium Phosphate |

| ECBC | Energy Conservation Building Code |

| ELV | End of Life Vehicle |

| EPR | Extended Producer Responsibility |

| ERP | Emission Reduction Potential |

| ESA | Ecologically Sensitive Areas |

| GIS | Geographic Information System |

| HCV | Heavy Commercial vehicles |

| ICD | Inland Container Depot |

| IRR | Internal Rate of Return |

| LCV | Light Commercial Vehicles |

| MRF | Material Recovery Facilities |

| MSW | Municipal Solid Waste |

| NDC | Nationally Determined Commitments |

| NHM | National Hydrogen Energy Mission |

| PAT | Perform Achieve and Trade |

| PPA | Power Purchase Agreement |

| PPR | Partial Producer Responsibility |

| PROM | Phosphate Rich Organic Manure |

| RCC | Reinforced Cement Concrete |

| RDF | Refuse Derived Fuel |

| REC | Residential Energy Consumption Survey |

| RECS | Residential Energy Consumption Survey |

| SPV | Solar Photovoltaic |

| STH | Solar Thermal |

| STP | Sewage Treatment Plants |

| SUV | Sport Utility Vehicle |

| T&D | Transmission & Distribution |

| TCO | Total Cost of Ownership |

| ToU | Time of Use |

| U-DCPR | Unified Development Control and Promotion Regulations |

| ULB | Urban Local Bodies |

| VRF | Variable Refrigerant Flow |

| BS | Bharat Stage |

| ENS | Eco-Niwas Samhita |

| UNITS | |

| kWh | Kilowatt hours |

| LPD | Liters per day |

| MLY | Million Liters per year |

| MTOe. | Million Tons of Oil Equivalent |

| MU | Million Units |

| MW | Megawatt |

| TPY | Tons Per Year |

Executive Summary:

This report on the Feasibility Assessment of Rapid Decarbonisation Potential for a ‘Net Carbon Neutral’ Pune Metropolitan Region (PMR) presents an in-depth study of the carbon emissions (CO2eq) in the PMR with a view to identify key areas of rapid carbon emission reductions in a various sector.

Following the PIC Policy Paper on ‘Making PMR Net-Carbon Neutral by 2030’ released in Jan. 2020, despite the long pause due to Covid lockdowns and restrictions, this study is an effort by PIC to rejuvenate the idea with a sense of urgency that is warranted by the impacts of Global Warming already causing serious hazards to livelihood and economy. Metropolitan areas being the major contributors of GHG emissions, the project of Net Carbon Neutrality for PMR as early as possible offers an opportunity for taking leadership action by this fast-growing Urban Conglomerate to demonstrate exemplary climate action. The feasibility study is a collaborative initiative between PIC and BP India towards moving forward on the Socio-Economic transitions that must take place for humanity to continue the path of progress.

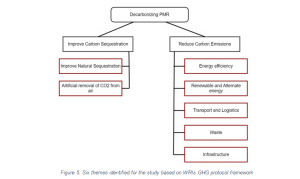

The report has selected 6 main themes for rapid decarbonisation as follows – 1. Energy Efficiency improvements, 2. Maximising Renewable Energy (RE) use with Solar and other non-fossil-fuel renewable sources, 3. Moving to Low Carbon Transport for PMR, 4. Waste Management improvements for reducing carbon emissions, 5. Infrastructure sector for reducing embedded as well as operational carbon emissions over the long life-cycle, 6. Enhancing carbon sequestration capacity of PMR, both natural and artificial for moving towards Net-Carbon Neutrality.

Taking the draft Development Plan (DP) of PMRDA as reference, the methodology for the report has been collaborative information exchange with several local experts in Pune as consultants/ researchers for the study. While this has provided a larger expert group to analyse the relevant data and information leading to the report. Unfortunately, this has also created use of different standards and units of measurements for different sectors and this needs to be normalised to the extent possible through iterative revisions of this ‘Draft Report’, as the project moves to implementation phase.

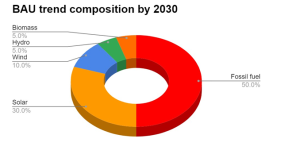

The largest potential for rapid decarbonisation of PMR are the energy (particularly the electricity sector), which is already undergoing the complex transition to clean and Renewable Energy (RE). In the context of PMR, the suitability of distributed generation of RE within the jurisdictions of the PMR offers great promise of even investing in a RE smart-microgrid that can have smooth handshake with the main grid which is still about 70% dependent on Fossil-Fuels.

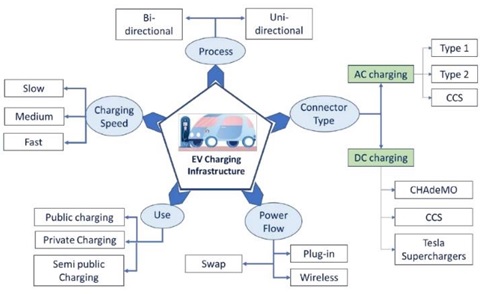

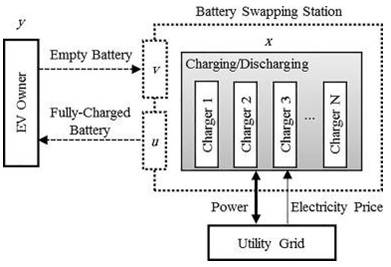

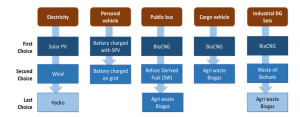

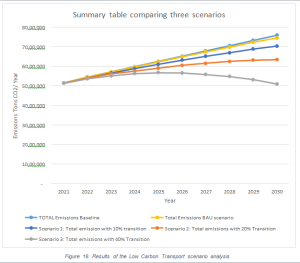

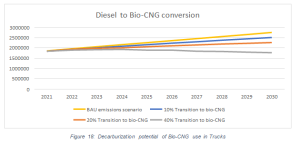

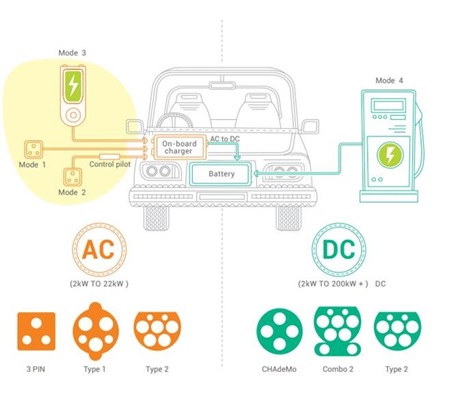

The next large potential is the transport sector, where shift to electric vehicles across all types has also already begun, aided by very supporting Govt. policies. While the RE vehicles will fast become popular for obvious economic & performance advantages, the challenge will be to create RE charging infrastructure to avoid increasing the grid-load which has only 28% share of RE. Creating a RE micro- grid would also help the transport sector to rapidly reduce the actual EV emission levels. In the interim, Bio-fuels or Bio-CNG can reduce the use of Diesel/Petrol towards decarbonisation. Hydrogen energy or storage options, though in nascent stage, open up very promising opportunities for the transport sector.

This feasibility report is aimed to provide high confidence for decarbonisation initiatives across PMR to help reduce the emission gap for Net Carbon Neutrality (NCN). Hopefully, the PMR can demonstrate very soon by 2025 through various pilot projects that rapid decarbonisation in a key sector can actually lead to significant reduction in emission levels to what can be off-set with natural sequestration +artificial removal, storage and use of CO2 by CCUS technologies including futuristic technology of direct removal of CO2 from air.

PIC will keep working on updating this assessment of actual numbers in this study and evolve strategies for undertaking a few pilot projects to demonstrate the real potential of deep decarbonisation of PMR by 2030 to approach Net Carbon Neutrality.

The report has not only tried to present an analysis of technology status along with Techno-Financial assessment where possible, and looked at Green Financing options to help accelerate the process.

Summary of the PMR Emissions scenario:

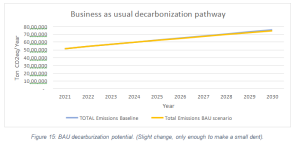

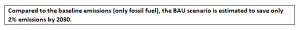

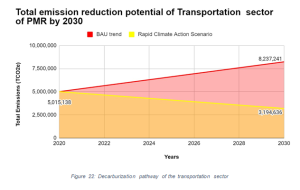

The graph below comparing the Rapid Decarbonisation of PMR with its Business-as-usual (BAU) trend is a clear eye-opener of the great promise of achieving lower level of carbon emissions than today. Hence, the reduced emission gap can be bridged with enhanced natural + artificial sequestration capacity without hurting the economic progress. Therefore, it is entirely feasible for the PMR to reduce its carbon emissions by 2030 and beyond compared to the current levels, despite increase in population and demand for resources.

Introduction:

The United Nations Population Fund notes that there has been an unprecedented movement from rural to urban areas across the world. By 2030 it is expected that 60% of the world’s population will live in urban areas. India will have its own share of megacities and the Pune Metropolitan Region (PMR) is one of the fastest growing urban areas in the country. A United Nations Human Settlements Programme (UN-Habitat) report shows that although cities are spread over 2% of the total land area, they contribute to 70% of GHG emissions. When urban expansion lacks planning, as is evident in most Indian cities, the energy consumption, mobility, and infrastructure can generate emissions, which could have been avoided in the planning stage.

Carbon dioxide equivalent (CO2eq) gas concentration has crossed 420 PPM (compared to pre- industrial average of 280 PPM) and is continuing to increase at 2 PPM every year. At the Paris Conference in 2015, over 195 countries agreed on serious voluntary commitments to reduce greenhouse gas (GHG) emissions, but there is still no sign of real global emission reduction. The concentration of GHGs if unchecked, will cause unprecedented global warming and make most parts of the Earth uninhabitable for human life within this century. With just over 1°C warming (above pre- industrial average) climate change effects are already visible in the form of rising heat, unusually heavy rains and flooding, intense and frequent cyclones, and an alarming rate of melting of polar icesheets. Globally school children are protesting lack of timely Climate Action by Governments and political leadership. In India, climate change is already causing heavy economic losses, and will further damage the economy, security, and human health in future.

Although climate impacts will be global, a tropical country like India will be far more vulnerable to it than the colder and higher latitude modern countries. At the Paris Climate Summit, India made significant NDCs for reducing the carbon intensity of development to 35 % below the 2005 level, so that the pace of economic development can be maintained without hurting the environment. While combating climate change will require well-coordinated global action, it must all start with local actions. This will require urgent moves towards a lower carbon footprint for all development activities, for which major cities of India like Pune must take pioneering leadership.

This report endeavours to nudge the geographic PMR to take up the challenge. PMR must initiate pioneering efforts to Achieve Carbon Neutrality and provide a replicable model for other Indian cities, to eventually make India carbon neutral, hopefully, by 2047 – the 100th years since our independence. The road to decarbonizing a city is never simple. It is not merely a switch to low carbon technologies, but requires a critical review of the city’s administrative capabilities, public infrastructure and the cultures of its people. Low carbon technologies may need administrative changes and/or behavioural changes of the citizens.

1.1 Carbon Neutrality

Even though the term is widely used carbon neutrality does not have a universal definition, nor a widely accepted international certification system. Murray and Dey1 (2008) note, the term currently appear to be ‘defined by popular usage’ (238). The key goal of carbon neutrality is to reduce the greenhouse gas (GHG) emissions, in the context of this study, of a metropolitan region. It involves reducing emissions through as energy efficiency measures, the built environment, building design, transport infrastructure, renewable sources of energy or offsetting balance unavoidable emissions. The process of achieving carbon neutrality consists of three main steps of Measuring, Reducing and Offsetting emissions.

Across the world, many cities have undertaken measures of carbon neutrality, while some already claim it. The way each city approaches carbon neutrality differs considerably. GHG frameworks and inventories are being developed by many cities and organisations.

1.2 What is Net Zero?

It should be noted that Net zero does not refer to zero emissions but is about achieving a balance between greenhouse gas (GHG) emissions being released to the atmosphere, and those being avoided or removed from the atmosphere. As it is impossible to stop emissions from sectors like agriculture and industry a goal of zero emissions will be a utopian one. Achieving net zero targets requires humongous reduction in emissions. The removal of emissions can happen naturally and artificially. The natural removal of emissions from the atmosphere takes place in photosynthetic organisms. These include vegetation and microscopic phytoplankton found in aquatic ecosystems. Artificial sequestration is termed as Carbon Capture, Utilisation and Storage or CCUS for short. Here, carbon is captured with the help of technological measures, it either utilized or stored in soil and oceans.

In this study for PMR, we have worked with several limitations, as seen in the table below.

| Issue | Description |

|

Gases |

The study mainly considers CO2EQ as the key GHG. However, we have included GHGs emitted during waste decomposition and treatment. Industrial emissions and air pollution are not considered. |

| Measurement

units |

We use Tons of CO2EQ equivalent as the standard measure in the report. |

| Accounting methodology | For energy, waste, transport and logistics, we use emissions within PMR

boundary. For infrastructure, we have considered embodied energy by using a life cycle analysis (LCA) software called One-Click LCA. |

| Boundaries | We use Pune Metropolitan Region (PMR) as the geographical boundary. |

| Scopes | We have considered Scope 1, 2, while for Scope 3 we have considered embodied energy in built infrastructure. |

1.3 About Pune Metropolitan Region (PMR)

Historically, Pune has been at the forefront of freedom movements. After independence Pune secured a position for itself as a seat of education and provided capable human resources in building the Indian economy. Its proximity to Mumbai rapidly transformed this educational city into an industrial hub. Today it is one of India’s largest automotive clusters. As the information technology revolution started in India Pune did not lag. The abundant supply of talented engineers ensured that the city was an obvious choice to India’s upcoming IT companies.

The automobile and the IT sectors triggered a large-scale influx of manpower from across the country. After around 1990 the city grew rapidly, with planned industrial areas and IT parks. This increased the spread of Pune Municipal Corporation (PMC) and the Pimpri Chinchwad Municipal Corporation (PCMC) as well as the major 3 Cantonment Regions. Unfortunately, the residential clusters in both the municipal corporations grew haphazardly in the fringe areas and villages surrounding their municipal limits.

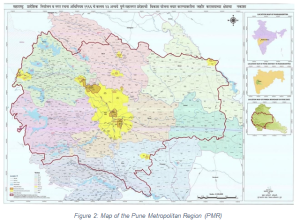

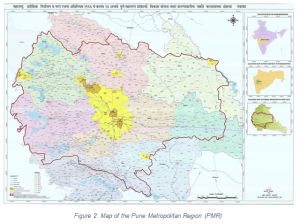

The Pune Metropolitan Region (PMR) was conceived as a region to merge the Municipal corporations, cantonment areas, municipal councils and village gram panchayats and form an integrated administrative area. The Pune Metropolitan Region Development Authority (PMRDA) is the planning and development authority of the PMR. The Government of Maharashtra established PMRDA to plan the development of Pune, Pimpri-Chinchwad and the surrounding area of 7,357 sq.km. The PMRDA was established on the 31st of March 2015 by the Urban Development department of Maharashtra, as an independent Autonomous body. It is headed by the Chief Minister of Maharashtra and has an IAS rank as the chief executive officer.

The PMR includes the cities of Pune and Pimpri-Chinchwad, the tehsils of Maval, Mulshi, Haveli and parts of the talukas of Bhor, Daund, Shirur, Khed, Purandar and Velhe. The PMR is a rapidly growing urban region with a large area of 7,357 sq.km, and a population of over 7.2 million (2018). It is likely to be inhabited by over 10 million people by 2030. The Draft Plan has 18 urban growth centres and 8 rural growth centres. The region is ideally suited for establishing sound climate-resilient planning with environmentally best-practices to achieve ‘Net Carbon Neutrality’, and this report is an effort to identify priority areas for decarbonising PMR and kickstart the activities leading to a Net-Zero city.

1.4 Vision

For a country like India the role of cities in mitigating climate change cannot be undermined. In the quest to meet and exceed the Nationally Determined Commitments (NDC) of the Indian government, the potential of cities to reduce emissions is humungous. While United Nations, World Bank and other agencies have suggested frameworks for decarbonising cities, and several cities across the world including PMR are in the Race to Net Zero, these pathways are largely skewed towards a developed infrastructure and competent administration. Unfortunately, both are lacking in most Indian cities. This project aims to provide a decarbonising framework suitable to meet the challenges and pressures of a developing region/nation.

We envision a low-carbon development strategy within the PMR, with significant reductions in the operating emissions, and an improved natural + artificial sequestration capacity within the region. This will be accomplished with efficiency improvements, rapid transition to Renewable Energy, leveraging on other low-cost technologies and putting together unique business models such that the decarbonisation process makes economic sense, is ecologically prudent and socially benign. Our goal is to make the decarbonisation model for PMR as one which paves the way for other cities to follow. As per the PMR Draft Development Plan, PMRDA intends to adopt elements of carbon neutrality and energy efficiency in its approach towards the planning and development of PMR. The concept is designed to increase the quality life of life and minimum resource consumption through:

- Compact Development

- Mixed-use, including habitation, offices, shops, restaurants and social facilities

- Minimized embedded energy

- Zero Carbon operation

- Excellent mobility (Train, Bus, local streets, highway access, bike trails, etc.)

1.5 The Emission Scenario of PMR

The table below summarises the emissions in PMR from Scope 1,2 and 3, estimated for the year 2030.

| CO2 eq. T/Year | CO2 eq. T/Year in 2030 (Current trend) | Percent of Total | |

| Scope 1 | 7,580,709 | 10,049,434 | 25.62% |

| Scope 2 | 10,873,200 | 20,729,780 | 52.85% |

| Scope 3 | 6,594,139 | 8,440,498 | 21.50% |

| Total | 25,048,048 | 39,219,712 | 100.00% |

| Natural sequestration capacity of PMR | 779,830 | 1,569,840 | |

| Emissions Gap to be offset | 24,268,218 | 37,649,872 | |

Table 1: This table summarizes the current emissions in PMR from Scope 1,2 and 3, and estimated for the year 2030.

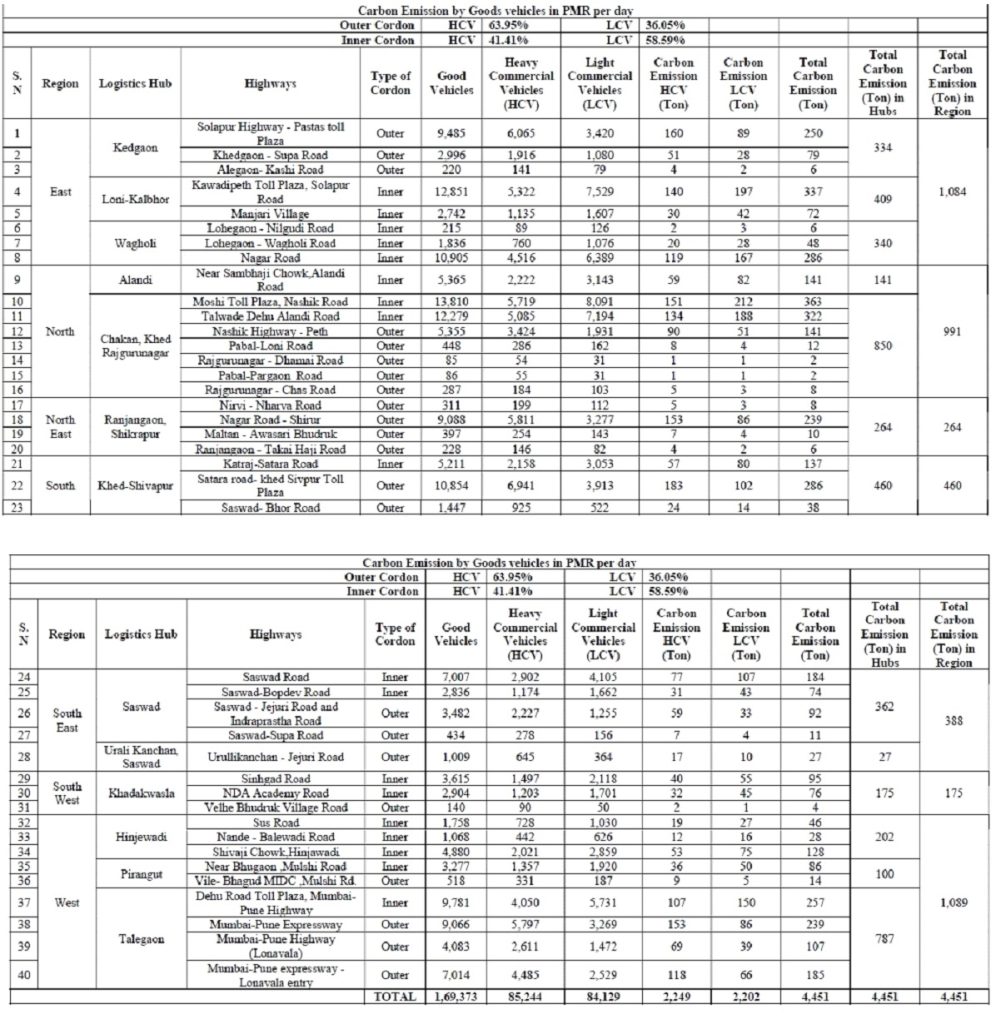

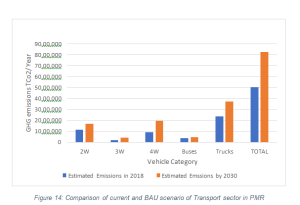

The challenge is to reduce and offset the 24 million tons of CO2 eq. emissions today and 37 million tons CO2 eq. by 2030 or later, within the PMR. Given below is a sector wise distribution of the emissions in PMR. The electricity and infrastructure sector contribute the most to the emissions at 43.4% and 26.3% respectively. The transport sector contributes to 23.5% of the total emissions of PMR; followed by waste sector at 6.9%. This report examines the challenges, identifies low-hanging fruits, and sets priorities for a comprehensive plan to decarbonise the PMR based on these sectors:

2. Methodology:

The draft of the Development Plan (DP) of the Pune Metropolitan region (PMR) has been recently made available for public viewing. This draft defines the geographic limits of PMR. The DP is yet to be passed in the state government. The PMR is thus a very recent formation and there is no data available of the new peri-urban and rural areas which are now part of PMR. We were thus restricted to the data from the Pune Municipal Corporation (PMC) and Pimpri Chinchwad Municipal Corporation (PCMC).

There have been several studies conducted within Pune city and PCMC. We reviewed such published reports and reached out to PMR, PMC, PCMC for data. The report uses several other sources of publicly available data.

To compile the baseline data of carbon emissions, identify areas of importance and decide the priority areas to work upon, we made six themes that make up the Scope 1 and Scope 2 emissions in PMR. We then deep dived into each of the thematic areas. In each theme we involved organisations who have expertise in the domain. Each of these organisations met with PMC and PCMC officials and other experts, made their own analysis, and made their set of recommendations. The reports comprised of their observations and analysis, and recommendations for decarbonizing pathways. Furthermore, we reached out to companies who have demonstrated capabilities in low carbon technologies.

2.1 Collaborating Organisations:

Many organisations contributed to this exercise. They are:

- See Green Solutions (renewable energy)

- Prakruti Organics (mobility)

- Poornam Ecovision (waste)

- Symbiosis International University, Infrastructure management (logistics and EV)

- Pune Knowledge Centre (EV)

- National Chemical Laboratory (Carbon capture, utilization, storage and sequestration)

- Symbiosis International University, Energy & Environment management (Financing)

- VK:e Environmental LLP & Sustainability Initiatives (Infrastructure)

- CCP Environmental Foundation (Water)

Besides these, the PIC team met some experts from other organisations, while some organisations contributed short notes of their technologies or solutions. Sentient Labs KPIT, Centre for Environmental Education, Ecological Society, ProEarth, Prima Plastech, Prayas, Parisar, Swach and Infosys contributed to this study.

2.2 Sources of Data

Sourcing reliable data posed a huge challenge as many organisations were reluctant to provide data. Nevertheless, we managed to get the data from the following organisations:

- Pune Divisional Commissioner’s office

- Pune Metropolitan Region Development Authority (PMRDA)

- Pune Municipal Corporation (PMC)

- Pimpri Chinchwad Municipal Corporation (PCMC)

- Pune Mahanagar Parivahan Mahamandal Limited (PMPML)

- Maharashtra State Electricity Distribution Company Limited (MSEDCL)

- Pune Petroleum Dealers Association

- Regional Transport Office, Pune & Pimpri-Chinchwad

2.3 The Six Themes of this Report

The Greenhouse Gas Protocol divides all emissions in three categories. Scope 1 GHG emissions are from sources located within the city boundary. Scope 2 emissions are those that occur in the production of grid electricity, heat, steam and/or cooling within the city boundary and Scope 3 emissions are those happening outside the city boundary.

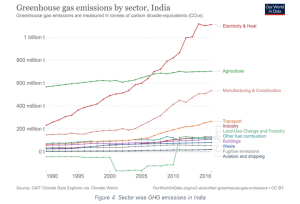

The sectoral contribution of carbon dioxide equivalent emissions for India is given in figure 1. About 68.7% of GHG emissions come from the Electricity Sector, followed by agriculture, industrial processes (19.6%), land-use change (6%) and forestry (3.8%), and waste (1.9%). There are several other sources of data which match with this ranking.

As per the World Resources Institute GHG protocol the emissions of a city can be classified into six main sectors:

- Stationary energy: this includes combustion of fuel in residential, commercial and institutional buildings and facilities and manufacturing industries and construction, as well as power plants to generate grid-supplied energy

- Transportation: these emissions are produced directly by the combustion of fuel or indirectly by the use of grid-supplied electricity

- Waste: This includes emissions arising out of solid waste and its incineration

- Industrial processes and product use: This comprises of emissions from industries which are from combustion in boilers, generators or other sources.

- Agriculture, forestry, and other land use: This includes emissions from livestock and changes in land use.

- Any other emissions occurring outside the geographic boundary as a result of city activities: Using the national sectoral emissions data and the WRI GHG protocol framework, we divided this project into six themes as mentioned earlier.

Reduction of carbon emissions is without a doubt the first important step towards decarbonisation. in this step we focus on the 5 major sources of emissions:

Energy Efficiency: The electricity supply to PMR is solely by the Maharashtra state Electricity Distribution Company (MSEDCL). MSEDCL estimates distribution losses for Pune city zone to be around 8%. There is also scope to improve efficiency in government buildings by switching over to low energy devices and among the small and medium Enterprises in PMR.

Renewable Energy: As per the State Economic Survey 2020-21 Maharashtra has a potential capacity of 21,250 MW, but as on November 30, 2020, the installed capacity was 9,817 MW. A rapid shift to renewable energy will require changes in the state’s RE policies. With respect to biomass the biggest opportunity is using crop residue to reduce fuel and converting municipal solid waste (MSW) to fuel. Both the options pose a challenge. Farmers either burn their crop Residue in the field or store it aside for cattle fodder. Similarly, municipal solid waste is largely in the unsegregated form, which cannot be used without further treatment.

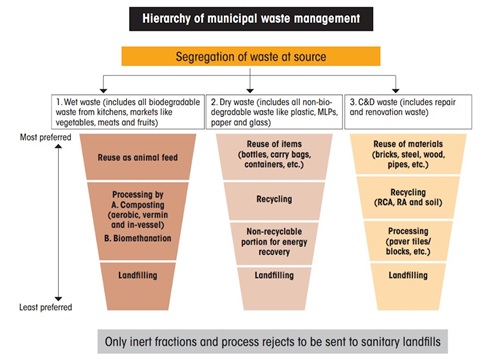

Waste: Untreated Municipal solid waste (MSW) landfills can pollute underground sources of water and pose a threat to human health. On the other hand, incineration leads to carbon dioxide emissions and adds hazardous dioxins to the air. It is thus imperative that MSW is segregated and treated properly. Technologies of converting waste into fuel have advanced considerably, and offer solutions to emission reduction.

Mobility: The population density of cities in the developing countries is higher than in the developed world. The urban sprawl in PMR has been haphazard, rather than following a path of transit-oriented development. This imposes several problems in city commuting. Although Pune, and other cities in developing countries, have comparatively lesser cars, the roads are being designed for cars and not public transport.

Infrastructure: An old city like Pune, has inherited carbon-intensive infrastructure, built with little consideration to natural light, natural cooling and rain water harvesting. This sector poses tremendous opportunity to save emission.

2.4 Emissions Considered in this Study

The Carbon footprint of a city is the total amount of greenhouse gases (expressed in equivalent metric tons of Carbon Dioxide i.e., tCO2 eq.) that are emitted directly or indirectly as a result of human activities by individuals, organizations or regions. The Greenhouse Gas Protocol further divides CO2eq emissions into three categories: Scope 1 – these are emissions resulting from GHG emissions from sources located within the PMR boundary), Scope 2 (these are GHG emissions occurring as a consequence of the use of grid-supplied electricity within the PMR boundary) and Scope 3 (all other GHG emissions that occur outside the city boundary as a result of activities taking places within the PMR boundary, for example from the use of cement, steel and goods and services.

| Sectors and sub-sectors | Scope 1 | Scope 2 | Scope 3 |

| STATIONARY ENERGY | |||

| Residential buildings (electricity consumed) | Yes | ||

| Commercial, Institutional buildings (electricity

consumed) |

Yes | ||

| Manufacturing industries (electricity consumed) | Yes | ||

| Built infrastructure (embodied energy) | Yes | ||

| Built infrastructure (operational energy) | Yes | ||

| TRANSPORTATION | |||

| Private vehicles (fuel consumed) | Yes | ||

| Public transport (fuel consumed) | Yes | ||

| Aviation | No | No | |

| WASTE | |||

| Disposal of solid waste generated in the PMR | Yes |

| Incineration of waste generated in the PMR | Yes | ||

| Sewage generated and treated in the PMR | Yes | ||

| INDUSTRIAL PROCESSES AND PRODUCT USE (IPPU) | |||

| Industrial processes | No | ||

| Product use | No | ||

| AGRICULTURE, FORESTRY, AND LAND USE (AFOLU) | No | ||

| Livestock | No | ||

| Land | No | ||

| Other agriculture | No | ||

| Travel of Punekars | No |

Table 2: The table shows the emissions included in this study.

2.5 Major Assumptions made in this Report

The analysis in this report is compiled from a carbon neutrality perspective, and does not include other climate actionable like reducing risks, increasing resilience, improving ecological balance or addressing pollution.

- There was no data available from the newly added suburbs, peri urban areas and villages which constitute the Pune Metropolitan region. However, data was available from PMC and Considering the current spread of population, the industrial hubs and IT parks, we assume 90% of the emissions are from PMC and PCMC alone, and whenever a data point is extrapolated for PMR, it is on this assumption.

- The population growth for PMR is taken from the PMR Development Plan (See Table 3)

|

Year |

PMR Population |

Year |

PMR Population |

Year |

PMR Population |

Year |

PMR Population |

|

2016 |

6,652,939 |

2021 |

7,695,887 |

2026 |

8,736,962 |

2031 |

9,798,579 |

|

2017 |

6,854,460 |

2022 |

7,893,671 |

2027 |

8,939,660 |

2032 |

10,011,209 |

|

2018 |

7,062,086 |

2023 |

8,096,539 |

2028 |

9,147,060 |

2033 |

10,228,452 |

|

2019 |

7,276,000 |

2024 |

8,304,620 |

2029 |

9,359,272 |

2034 |

10,450,409 |

|

2020 |

7,489,914 |

2025 |

8,518,048 |

2030 |

9,576,407 |

2035 |

10,677,183 |

Table 3: Population projections for PMR

- The projections for the energy consumption and vehicular traffic for the year 2030 are compounded based on two major factors:

- Population growth rate: The growth of population in PMR (including migration) is considered to be 24%, by PMR.

- Projected GDP increase: The rate of GDP growth is considered 4%, by PMR. This makes up a multiplication factor of 1.898 for the year 2030.

Electricity:

3. Electricity Sector – Status, Pathways and Technologies

The Electricity Sector is the biggest emitter of greenhouse gases. Improving its efficiency is the first critical step in the decarbonising journey of PMR. There are multiple areas in PMR – geographic and administrative – where the use of energy can be made much more efficient. In this path, measuring the energy consumed is the first step followed by an analysis of Renewable Technologies and pathways for decarbonization. In the following paragraphs the sector wise electricity demand and that for different types of fuels are presented.

3.1 Status of Electricity Sector in PMR

Historical electricity demand numbers were available for Pune Municipal Corporation (PMC) and Pimpri Chinchwad Municipal Corporation (PCMC). Based on these, the demand was segregated into estimates for domestic, industrial and commercial electricity requirements for PMR.

PMRDA, PMC and PCMC have published drafts of long-term development plans. Following table gives the latest numbers for sector wise electricity consumption in PMC, PCMC and the emissions estimated from them (see annexure 1 for emission factors). This comprises of Scope 2 emissions within PMR.

| SCOPE 2 | Electricity

consumption |

2018-19 in PMR | Estimated in 2030 in PMR

(assuming 50% RE) |

||

| Electricity

Consumption |

Share (%

of total) |

M kWh | Emissions (T

CO2) |

M kWh | Emissions

(T CO2) |

| Residential | 45.1 | 5,977 | 4,900,939 | 16,110 | 9,343,800 |

| Industrial | 28.5 | 3,778 | 3,098,259 | 10,184 | 5,906,720 |

| Commercial | 16.0 | 2,122 | 1,739,697 | 5,719 | 3,317,020 |

| Municipal | 5.3 | 702 | 575,387 | 1,891 | 1,096,780 |

| Others | 4.8 | 635 | 520,989 | 1,713 | 993,540 |

| Agriculture | 0.3 | 46 | 37,930 | 125 | 72,500 |

| Total | 100.0 | 13,260 | 10,873,200 | 35,741 | 20,729,780 |

Table 4: scope 2 emissions of PMR and sector wise electricity consumption.

There is also a significant scope for improving the efficiencies of fuel consumption within PMR. We received the fuel consumption data for the Pune District from the Petroleum Dealers Association. We also got a breakup of the fuel consumption by the type of fuel (refer to the table 5).

| SCOPE 1 | 2018-19 PMR | Estimated in 2030 PMR | |||

| Petroleum consumption | Emission Factor | Tons | Emissions (T CO2) | Tons | Emissions (T CO2) |

| LPG | 3.61 | 469,515 | 1,694,949 | 501,993 | 18,12,193 |

| CNG | 2.75 | 47,835 | 131,546 | 51,978 | 1,42,939 |

| Petrol (Gasoline) | 3.09 | 591,817 | 1,828,715 | 643,072 | 19,87,092 |

| High Speed Diesel | 3.14 | 1,250,159 | 3,925,499 | 1,358,430 | 42,65,470 |

| Total | 7,580,709 | 10,049,434 | |||

Table 5: Scope 1 emissions of PMR and emissions based on fuel type.

The consumption of LPG is primarily for household and commercial use, while the other fuels are primarily for vehicles. Nevertheless, all this consumption falls in the Scope 1 emissions.

According to the Maharashtra Economic Survey of 2020-21, from the total Electricity demand in the state, 72% is being met by Fossil fuel Electricity (Thermal and Natural Gas) and 28% of Renewable Energy as per the state electricity mix. The challenge now is to reduce the demand of electricity and at the same time transition to Renewable Energy.

3.2 Pathways for Energy Efficiency

As shown in the earlier section, the challenge for PMR is to work upon the reduction of 25 million tons of CO2eq emissions. The first action towards this is to improve the existing energy efficiencies in the fuel consumption, and the second is to reduce the energy demand with the use of low carbon technologies and products.

The biggest opportunity undoubtedly, is in the space of improving the efficiency of use of electricity in the residential, commercial and industrial sectors and a significant opportunity for reducing the losses in the distribution grid. The Economic Survey 2021-222 mentions the poor efficiency of transmission and distribution of electricity in India, and highlights the urgency in improving it.

Similarly, the Bureau of Energy Efficiency3 (BEE) has identified Energy Efficiency (EE) as a key to reducing fuel consumption in India, and consequently reducing the emissions. BEE makes three major recommendations for improving energy efficiency in India4. The recommendations highlight the state government’s role in the improvement program.

- Proactive role by states in policy formulation and implementation: States must exercise powers under the Energy Conservation Act5 and formulate supporting policies and implementation rules to shift the focus from “policies in place” to “policies successfully implemented”.

- Strengthening the mechanism for data capture, management and public availability of data: SDAs should significantly enhance their engagement with state departments, electricity distribution companies (DISCOM) and private sector organisations beyond one-time data

- Enhancing the credibility of EE schemes: States must demonstrate an approach which includes enforcement and compliance checks. Rules related to mandatory energy audits, mandatory sale and purchase of BEE star labelled appliances will not be effective unless an inspection process is established and strengthened. States must also make independent monitoring and verification of savings integral to all energy efficiency (EE) policies and programs.

- Addressing the energy efficiency within PMR

There are enormous opportunities for efficiency improvements in every sector of the economy, whether it is buildings, transportation, industry, or energy generation.6

Electricity consumption, Scope-2, is the largest contributor (44%) to emissions of PMR. On the one hand, it is imperative that the consumption of electricity should be reduced by implementing energy efficiency and conservation measures; and on the other hand, we need to switch from fossil fuel to renewable energy. This will lead to a reduction in the Scope 1 emissions, and addition to the Scope 2 emissions. The following sections focus on energy efficiency measures to reduce the present emissions from electricity and fuel use.

- Addressing Energy losses in the distribution grid

Transmission and distribution (T&D) loss are essentially the amount of electricity that is not paid for by users. T&D losses are computed by the equation:

According to the NITI Ayog report7, power distribution is the weakest link in the supply chain of the power sector. Their study shows that distribution utilities are making major losses as a consequence of expensive long-term power purchase agreements, poor infrastructure, and inefficient operations, among others. These losses, in turn, prevent them from making the investments required to improve the quality of the power supply.

There is no recent figure available for the losses occurring within Pune zone, the MSEDCL website shows the data of 2017-18. For Pune Zone, the distribution losses are 10.75%.8 However, the Economic Survey 2020-21 of the Government of India estimates an average of 20.46% of electricity produced in India is lost in transformation, transmission and distribution.9 There are several well-known reasons for T&D losses:

- Within PMR, 11 KV and 415-volt lines in rural areas extend over long distances to feed fragmented loads over a large area. This results in high line resistance and therefore, high losses in the line.

- Distribution transformers are not located near consumer centres. This leads to the farthest consumers getting lower voltage and results in highline losses.

- Power factors in low tension distribution circuits normally range between 0.65 to 0.75. For a given load, if the power factor is low, the current drawn is high and losses proportional to square of the current will be more.

- Haphazard joints are usually subject to poor workmanship. Joints are a source of power loss; thus, they must be kept to a minimum. Uncontrolled growth in load centres within PMR has led to random joints and subsequent losses.

Table 4 shows the consumption of electricity in PMR (Scope 2). Considering figure of 20.46% T&D losses from the Economic Survey, the emissions that are wasted in energy distribution are 2,224,657 T CO2 e (Refer table 6). If MSEDCL is able to invest in improved infrastructure in the next 3 years, the reduction in emissions is shown as various scenarios in table 6.

The huge potential to save on the T&D losses within PMR by improving the infrastructure, is clear from this table.

| SCOPE 2 | 2018-19 PMR | 2030 | Emissions saved by reducing T&D losses | ||||||

| MkWh | T&D Losses (20.46%) | Emissions lost (T CO2) | MkWh | T&D Losses (20.46%) | Emissions lost (T CO2) | T&D losses at 10% | T&D losses at 12% | T&D losses at 15% | |

| Energy consumption M kWh |

13,260 |

2,713 |

2,224,660 |

35,741 |

7,313 |

5,996,339 |

2,930,762 |

3,516,914 |

4,396,143 |

Table 6: An estimation of the T&D losses and potential emission savings from reducing T&D losses

- Addressing Energy Efficiency in households/ residential sector of PMR

Prayas10 has done seminal work in understanding the household inefficiencies of electricity usage. Furthermore, the Niti Ayog has put up a study and made recommendations for energy efficiency. We studied these and other reports and make the following recommendations for improving energy efficiency in PMR.

As per the conditions laid out by UDAY, it was mandatory for state governments to reduce the AT&C loss to 15% and the ACS-ARR gap to zero, by 2018-19. This was to be brought out by compulsory smart metering of large customers, upgradation of distribution infrastructure, and implementing energy-efficiency measures. MSEDCL must immediately work upon these measures to reduce pilferage and improve distribution efficiency.

The energy saving potential in the residential sector can be realised with a three-pronged approach:

Lighting: Government programmes like the Unnat Jyoti by Affordable LEDs for All (UJALA), have met with success. The Bureau of Indian Standards (BIS) mandates LED lights in India to conform to safety and performance standards. The BEE has a star labelling system for LED lamps, however, a study in UP and Maharashtra by Prayas found that compliance with these regulations is weak. Their survey of 400 retailers across 8 cities found that half of the LED bulb brands available in the market do not conform with the BIS standards for safety and performance.11

The central government launched the Street Lighting National Program (SLNP) to replace conventional street lights with smart and energy efficient LED street lights. Under this program the state-owned Energy Efficiency Services Limited (EESL) is working across India, to replace the conventional street lights with LED energy efficient street lights. LED street lights are equipped with Central Control and Monitoring System (CCMS), which allows remote monitoring and operation. This ensures that street lights are automatically switched on, once the sun sets and switched off after dawn. In Maharashtra 8,18,225 street lights were changed. This resulted in a saving of 550 MU of energy Maharashtra and emission reduction of 0.45 million tons of CO2eq.

Cooling: Summer, in many parts of India, is notoriously getting warmer. Prayas12 estimates that about 50 million fans, 8 million air-coolers, and 4.5 million air-conditioners are annually sold in India. Their sales have grown steadily over the last few years and are expected to increase. BEE has revised their standards, and the new 5-star ceiling fan consumes half as much electricity as compared to a non-star rated fan.

There are some interesting observations from the survey conducted by Prayas.13 About 32% households in Maharashtra either did not know about the star-labels or reported owning a non-star rated air conditioner, which indicates a low awareness about the energy efficient device programme. In the survey, Prayas reports an average temperature setting of 22 degrees Celsius (standard deviation = 2.9) in Maharashtra.

Household appliances: Refrigerators are ubiquitous appliances in modern kitchens. Frost-free refrigerators are usually larger, cost more, consume more electricity, and do not require manual defrosting as compared to direct-cool refrigerators. More than 10 million refrigerators are sold annually most of which are direct-cool refrigerators. Standards and Labelling (S&L) programme is mandatory for both types of refrigerators, thus no refrigerator can be sold in the market without a star label.

Like most cities in India, the penetration of television sets is very high in PMR. Many houses have more than one TV set. Modern LED TVs consume less power than conventional Cathode Ray Tubes. Here too, Prayas finds that most households are not aware of star ratings for TV sets.

Many newer suburbs of PMC and PCMC do not have a piped water supply, forcing housing societies and bungalows to use electric water pumps. Water pumps are used from half an hour to one hour per day on an average. Bungalow pumps usually consume about 1 horsepower (746 Watts), and large residential societies use higher powered pumps. The daily use of water-pumps can significantly add to the household’s electricity consumption.

- Star Ratings and efficient lighting

Using star rated equipment is advisable. It ensures not only reduction in consumption, but also better economics by way of reduced electricity bills. If we consider annual savings (units of electricity as well as in bill) for a typical 250 L frost-free refrigerator, the following table can be of use.

| 2021

Star Rating |

Annual electricity

consumed in kWh (units) |

Power bill Rs 6.4/unit | Savings in bill (Rs)

compared to 1 star |

| 1 | 320 | 2051 | Baseline |

| 2 | 256 | 1638 | 413 |

| 3 | 205 | 1312 | 739 |

| 4 | 164 | 1049 | 1002 |

| 5 | 131 | 838 | 1213 |

Table 7: Typical Star Rating for Frost Free Refrigerators and Annual Consumption

Moving from a baseline single star refrigerator to a 5 star one, there is reduction in electricity consumption by almost 60% Naturally, the electricity bill would also reduce, as can be seen in column 3 of the above table. Other such examples can be given.

- BLDC motors for ceiling fans

Household ceiling fans are usually induction motors consuming 70 to 80 watts power. Brush less Direct Current (BLDC) motors are now used to make fans that consume less energy, without compromising on the air delivery. BLDC motors are highly energy efficient and have longer life. Most of the BLDC ceiling fans are 5-star rated and consume 25-40 watts of energy, which is nearly 40-70% less than the conventional fans.

| Wattage | Consumption W/hour | Daily Consumption Wh | Yearly Consumption kWh | Savings in kWh |

| Regular Fan 75 W | 75 | 1125 | 410.62 |

246.37 |

| BLDC Fan 30 W | 30 | 450 | 164.25 |

Table 8: BLDC Fan motor efficiency and savings:

- Addressing Energy Efficiency in the Commercial Sector

With GDP growth, the demand for electricity has increased drastically in the commercial sector. In commercial buildings, the annual energy consumption per square meter of the floor area is over 200 kWh with air-conditioning and lighting being the energy guzzling applications. As commercial establishments are business clients, it is possible to mandate efficiency measures of efficient lighting and appliances, power factor and solar heating. This has a direct benefit of lowering business costs for them, and hence is the ‘low hanging fruit’ in PMR.

TERI’s study14 in the commercial sector shows a significant potential for efficiency, ranging from about 7% in 2021, 15% in 2031, and 18% by 2041. This can lead to 3 million TCO2 eq., 13 million TCO2 eq., and 34 million TCO2 eq., respectively.

Warehouses, hotels, restaurants, shops, malls, markets, offices, institutions, large, service providers and hospitals make up the commercial sector. The MSEDCL data shows the total annual electricity consumption of the commercial sector in PMR as 2,122 MU.

All the measures suggested in the ‘residential sector’ for PMR are applicable to the commercial sector.

- Addressing energy consumption in the Industrial Sector

As mentioned earlier, it is reasonable to assume that industry competitiveness is affected by inefficient power consumption, and every large industry will make efforts to minimise their energy use with efficient technologies.

We thus focus our attention on the MSME sector in PMR, which has a huge potential to reduce emissions with relatively less efforts. CEEW has made a set of recommendations for energy efficiency improvement in the MSME sector. Learning from other countries on energy efficiency measures is very important for India’s MSME sector. Japan has developed a carbon reduction reporting system for SMEs which has mandatory and voluntary reporting to the Tokyo Municipal Government (TMG).15 Based on these inputs, the TMG educates the SMEs about energy efficiency strategies to put them on the path of energy saving.

In the MSME sector, there are two key issues to be addressed in energy efficiency:

- Lack of Information: Formal or informal information and knowledge sharing mechanisms are nearly With the MCCIA and other trade organisations, the PMR can get this in place.

- Capacity building: Very often MSMEs are unable to spend on seemingly ‘non-business’ Most firms are unable to attract and retain talent necessary for such measures. Moreover, there are no ‘off-the-shelf’ measures that they can refer to.

To address these, PMR needs:

- Institutional reforms: Various state departments of industry participate minimally in implementing centrally funded support Increasing their participation and contribution would significantly improve the outcome of existing schemes.

- Energy benchmarking for MSMEs: There is a lack of any benchmarking data of energy use for Associations and Chambers like the Mahratta Chamber of Commerce (MCCIA), NASSCOM, and others can facilitate this and help the transition to an efficient MSME sector.

- Energy audits: Mandatory MSME energy audits must be incentivised within PMR. This will assist reducing costs of MSMEs and increasing their

The industrial enterprises within PMR comprise mainly of ancillary units of automotive companies, contract manufacturers like machine shops, fabrication, moulding, casting and forging units and small and medium electronics industries. The most significant consumption of energy in the industrial sector is in motive power, heating and cooling applications. It is reasonable to assume that in times of hyper- competition every large industry will try to minimise their energy consumption by using efficient technologies. Based on this assumption we do not see a significant scope for increasing energy efficiency within large enterprises. However, as per the BEE report, there is a huge potential for large industries to save energy by using energy efficient motors. Energy-efficient motors are easily available and operate with efficiencies of 3 to 4 percentage points higher than standard motors. Energy-efficient motors operate without loss in efficiency at loads between 75 % and 100 % of rated capacity. This can result in major savings.16

The BEE also has identified the MSME sector to have tremendous potential for improving energy efficiency.17 As per BEE, the major challenges here are:

- Use of obsolete and inefficient technologies

- Limited access to new technology and product innovation

- Lack of awareness of best practices

- Weak institutional support framework

- Inability to attract trained manpower

Most of the major industrial areas within PMR are in cluster formation, thus making it feasible to implement measures focusing on MSMEs. Moreover, measure of energy efficiency will directly improve the profitability of MSMEs, and hence there is a very high probability that the measures will be addressed.

- Addressing Energy Consumption in the Municipal Sector

Many of the PMC and PCMC old buildings have outdated electrical infrastructure, including non-star rated air conditioners and inefficient ceiling fans. Switching over to efficient devices will significantly reduce the energy footprint of PMC and PCMC. In the case of streetlights, the conventional low pressure mercury vapour fluorescent tubular lamps can be replaced by LED lights. The Mercury Vapor Lamps emit about 30 lumen / Watt. Whereas, the LED lamps produce around 70 lumen / Watt. Moreover, the LED lights can be dimmed and also the wavelength (colour) of the light can be varied from yellow to warm, true daylight and bright white.

Since the consumption of LEDs is lower, they can be effectively and economically integrated with Solar power. Solar LED Street lighting is a cost-effective solution for parking lots, parks, streets, airports, and other applications, where providing electricity may be difficult and often expensive. Municipal buildings have electric water pumps. Converting all electric motors to energy efficient ones is also an option. Such options are being implemented in phased manner. Most of the streetlights in PMR are already converted to LED. Hence, there is no further action warranted in this regard. E.g., PMC has completed converting 90% of the streetlights to LED lights. It has reduced the consumption considerably (by around 50%).

Every public building in PMR must use motion-controlled switches for lighting common areas like passages and lobbies. Infrared or sound sensors can detect when someone enters a room. These controls are called “occupancy sensors.” They turn the lights off when they no longer sense anyone in the room, protecting against energy loss from leaving lights on when no one is using them. Occupancy sensors are useful for rooms not constantly occupied: bathrooms, guest rooms, basement record rooms, and so on.

Municipal sector represents consumption by applications such as street lights, water supply systems and infrastructure, sewage handling and pumping, etc. The electrical consumption in 2019-20 by the Municipal sector of PMR was about 702 MU, representing about 5.3% of the total electricity consumption by PMR.

- Addressing energy Consumption in Agricultural Sector

PMR is highly urban and Industrialized. Agricultural land in the region is only about 35% as per the Draft DP. Moreover, the electricity and energy consumption of the agriculture sector in PMR is considerably low, about 46 MU annually. This is only about 0.3% of the total annual electricity consumption of PMR.

3.3 Recommendations for Energy Efficiency Implementation in PMR

BEE has evaluated the impact of energy efficiency on carbon emissions. It is expressed in terms of MTO eq., i.e., Million Tons of Oil Equivalent. One Ton of Oil will produce 3.1 T of carbon dioxide. Hence 1 MTO eq. would produce 3.1 million Ton carbon dioxide.

For PMR, based on the energy consumption and conservation potential derived in this report, we estimate the emission reduction (emission factor of Indian electricity 0.82 T/MWh). The results can be tabulated as given below.

| Sectors in PMR | Energy Consumption (MU) (2018-19) | Emissions | Potential Energy Savings (MU) | Potential Emissions Saved (T CO2) |

| (T CO2) (2018-19) | ||||

| Commercial | 2,121 | 1,739,697 | 354 | 290,437 |

| Residential | 5,977 | 4,900,939 | 1,714 | 1,405,643 |

| Industrial | 3,778 | 3,098,259 | 716 | 587,844 |

| Total | 11,876 | 9,738,895 | 2,785 | 2,283,924 |

Table 9: Potential Emissions saved by switching to energy-efficient technologies

The energy consumed and total carbon emissions, in the three sectors of PMR in 2018-19 are shown in the table above. The energy saved and emissions avoided by converting to energy-efficient technologies in the PMR will result in a considerable reduction in energy consumption and, as a result, a reduction in total carbon emissions. The above table’s last two columns depict a futuristic/potential view of PMR by decarbonizing existing systems.

| Sector | Appliance | Present (MU) | Savings (MU) | Savings (TCO2) |

| Residential | Geyser | 1,466.90 | 488.97 | 400,951 |

| Residential | Ceiling fan | 761.10 | 405.92 | 332,853 |

| Industrial | Motors | 2,455.94 | 368.39 | 302,081 |

| Residential | Tube light | 549.90 | 274.95 | 225,457 |

| Residential | AC 1.5 ton | 1,727.43 | 203.23 | 166,646 |

| Commercial | AC 1.5 ton | 1,539.68 | 181.14 | 148,534 |

| Residential | Television | 315.19 | 171.92 | 140,977 |

| Total | 8,816.13 | 2,094.51 | 1,717,499 |

Table 10: Actions that are possible with regulation within PMR’s scope.

Thus, with energy efficient appliances and machines there is a potential to improve energy efficiency by approx. 23%.

- 100% metering, using AI/ML technologies to reduce supply disruption and for predictive

- Conduct a PMR level Residential Energy Consumption Survey (RECS). This will assist in capturing household consumption characteristics. Periodically collecting such information is crucial for informing and evaluating measures of managing the household demand.

- Awareness, affordability, and availability of star-rated ceiling fans must increase to facilitate their wide-scale adoption.

- The Carbon Neutrality Cell of PMR must devise a communication strategy for quick adoption of energy efficient devices by households in PMR.

- PMRDA and CREDAI should chalk out a plan to phase out inefficient appliances in new residential A strategy to shift to BLDC fans and LED lamps in new tenements and motion sensor lights in common areas of residential societies.

- Ensuring the availability of good quality LED bulbs to sustain the on-going market transformation.

- Assuming that with the increase in warming in climate, the need for space cooling appliances in households would go up, focused efforts would be needed to evaluate and improve the performance of fans, coolers and ACs knowing that a large proportion is currently locally made.

- Accurate and prompt metering & billing can help build consumer trust while also help detecting theft and tampering thereby improving the billing revenues.

- Under the Street Lighting National Program (SLNP) PMR must immediately move to replace conventional street lights with smart and energy efficient LED street lights and Central Control and Monitoring System (CCMS). This would allow remote monitoring and operation and result in energy saving.

- MSEDCL needs a significant improvement in the billing efficiency through better metering. They must utilise the central government reform scheme to achieve 100% metering with prepaid or smart meters. There is much to learn from other states, especially Manipur, where prepaid metering has reduced thefts and increased collection; and Gujarat, where the DISCOM was able to significantly reduce technical losses through investment in grid improvement.

- In Delhi, Surat, Ahmedabad, Kolkata and Mumbai, private licensees are relatively more efficient and the distribution franchisees have helped bring down distribution losses significantly. Niti Ayog report18 shows that higher private participation in distribution holds out the possibility of greater efficiency. Franchisee models have been successfully implemented in Bhiwandi, where there have been rapid improvements in metering, billing, and Improving the energy efficiency is a necessary and a relatively low investment measure that is critical for PMR Carbon Neutrality. The residential sector being the largest consumer of electricity, will become the focal point, followed by MSMEs. MSEDCL must gear up to reduce the excessive T&D losses, as this will contribute towards reduction of Scope 2 emissions of PMR.For successful implementation of energy efficiency program, an iterative program is needed:

| Action | Constituent / Component | Drivers / Interventions |

| Measuring current use (100%) | Electricity, Water, Fuels, Other Resources | Metering, Regulations, Incentives, Penalties |

| Reducing Consumption | Electricity, Water, Fuels, Other Resources | Awareness, Behaviour, Pledges, Economics, Energy Efficiency, Planning & Layouts, Incentives, Penalties |

| Switching to Alternative Sources | Renewables, Sustainable, Recycled, Upcycled, Circular | Life Cycle Emissions, Life Cycle Cost, Economics, Local, Hybrids, Smart Governance |

| Evaluation | Per Capita Consumption &, Emissions, Air Quality, Water Quality, Per Capita Trees/Vegetation | Economics (expenses on Energy, Health, Food, Water, Waste), Equitable Availability, Autonomy at Local Level, Sustainable Development Index |

A multi-pronged approach, which considers all the following, will help achieve the goal.

- Reduce demand for all products and services by building awareness, making conducive policies, encouraging socially responsible behaviour and taxing emissions.

- Effectively deploy energy efficiency measures; conduct energy audits, identify energy conservation opportunities, evaluate them vis-à-vis emission reduction potential as well, record reductions.

- Capture all waste heat to cater to heating and cooling applications.

- Reduce vehicular fuel consumption by better planning of city and spaces, creating satellite hubs as population countermagnets, where daily commute would be reduced and brought down to cycling or walking.

- Improve public transportation systems and networks to effectively address energy consumption in daily commute.

- Undertake human resource development through appropriate training and skill development programs.

- Monitor the progress and regularly run promotion as well as awareness campaigns around it.

3.4 Water Energy Nexus

The relationship between water and energy is not currently widely acknowledged. However, it is known that treating water for human and treating water for human and industry consumption and moving treated water to the consumer is extremely energy intensive. Every 1 litre of water that passes through a water system represents a significant energy cost. Improving efficiency from both the supply and the demand sides would allow countries to reduce resource scarcity and maximize the benefits provided by existing Water & Energy infrastructure.

The energy intensity of water use (also called embodied energy) is the total amount of energy, calculated on a whole-system basis, required for the use of a given amount of water in a specific location. While energy sources other than electricity are occasionally used for water supply and treatment, most water distribution, treatment and wastewater treatment plants use electricity.

- Water Supply in PMR

Whenever water is lost to leaks, energy and cost of energy in that water are also lost. Many distribution systems are leaky. In many countries most water is lost before it reaches end user. Developing countries 33% to 50% lost to leak with 50% lost in India. Typical energy audit findings in pumping stations show inefficient pumps and motors mismatched in head and flow, inadequate pipe sizing, excess contract demand, system over design in Indian cities.

In case of PCMC, the total Water Treatment plants needed 77,592.40 MWh electricity leading to 63,625.77 TCO2eq GHG emissions annually in 2020-2021. And up to 50% of this energy, emissions and costs can be saved by prioritizing water efficiency.

The PMC has a network of 2,360 km for daily water supply with pipelines that are 800 mm and 100 mm wide. The water treatment plant capacity is adequate at 1,768 MLD for PMC. PMC population is currently 78,93,671, so assuming per capita 150 litre daily consumption, the city water demand is only around 1,184 MLD. According to the irrigation department data, PMC borrows 1,732 MLD water per day and also additional 310 MLD from groundwater, making it 2,042 MLD per day. Approximately, 80% of this exits as sewage making the daily volume 1634 MLD. This water needs to be reduced, reused and recycled.

- Sewage Treatment

The water treatment requirement for PMC is around 1,500 MLD daily including Khadakwasla and Bhama Askhed projects. But total installed Sewage capacity is only one third at 567 MLD. And these STPs are currently energy intensive with most efficient plant requiring 2 MWh energy for 1 MLD to more inefficient ones requiring up to 20 times more energy. If these are retrofitted to be more energy efficient, they will leave room to add additional STPs to ensure healthy rivers and water-bodies for citizen’s well-being.

The GHG emissions from current waste water treatment energy use is approximately 73,993.02 TCO2eq yearly, given current usage of 90,235.4 MWh annual electricity consumption. The energy intensity of these STPs is also currently very high. Reducing demand and using efficient STPs will reduce wastages not just in terms of GHGs and energy but cost of maintenance as well.

As per the 74th amendment about ULBs to the constitution, Maharashtra Municipal Corporations Act and Maharashtra Municipal Councils Act, municipalities are mandated to collect, remove, treat, and dispose of sewage. The MJP (Maharashtra Jeevan Pradhikaran)19 was mandated for wastewater treatment in rural areas. However, no such function is currently carried out by MJP.

Villages within PMR currently have inadequate sanitation facilities. The untreated sewage is discharged into the natural sewer or low-lying areas or directly into rivers/water streams. Thus, the river pollution level has breached the threshold levels. Poor sanitation facilities in remote areas are posing serious environmental damages due to the discharge of untreated sewage and open defecation to a certain extent. Beyond STPs, rapidly introducing recycling water by reusing treated wastewater for beneficial purposes such as agricultural and landscape irrigation, industrial processes, toilet flushing, and replenishing a ground water basin is needed to reduce water demand.

- Groundwater Usage

Irrigation is the largest consumer of freshwater resource across the world accounting for 70% withdrawals. Globally, out of about 301 million ha irrigated land, about 38% is dependent on groundwater. In India, about 38 million ha of and is irrigated by groundwater resources. Food security, therefore, will be increasingly affected by the status of groundwater in India’s aquifers.20

Pune Metropolitan Region falls under the Deccan trap volcanic groundwater province, which proves to be a good aquifer given that the rock is highly weathered. However, the interflow horizons such as red boles tend to become clayey and sometimes reduce the aquifer properties. With increasing allocations to non-agricultural sectors like industry and urban centres, competition and conflict around water resources in general and groundwater in particular will only increase in PMR.

Pune’s groundwater pockets are depleting as a result of the city’s rapid expansion, inadequate controlling functionaries and a biased approach to use of surface water sources. The shallow, weathered-fractured layers of basalt rocks have been tapped through the large diameter-dug wells (also called open wells) for many centuries. However, the last six decades have seen an explosion in the number of wells in Maharashtra, so much so that the yield per well since the 1990s has seen a steady decline. This implies that the aquifer storage is now being used by many more sources than ever before, an increase by five times over the last 50-60 years. Results from sample surveys regarding groundwater extraction, showed nearly 4 TMC of annual groundwater extracted in Pune city, which was around double the quantity recorded nine years before.21

Protecting the natural recharge zones that connect watersheds to Pune’s aquifers is the need of the hour. The public recharge systems must be based on the main recharge zones identified for each aquifer in the city. An expert-led groundwater governance framework for the city, along with an aquifer mapping exercise and Participatory Groundwater Management models needs to be integrated in city planning.22

- Emission Reduction Potential of Water Sector

Currently, water management remains heavily dominated by traditional, human‐built (i.e. ‘grey’) infrastructure and the enormous potential for NBS remains under‐utilized. NBS include green infrastructure that can substitute, augment or work in parallel with grey infrastructure in a cost‐ effective manner.

Energy represents the largest controllable cost of providing water or wastewater services to the public. Energy costs often one of the top 3 O&M costs in this sector. Energy efficiency interventions in water supply systems emission reductions in municipal water supply system production fuel consumption reduce greenhouse gases emission power plant pumping system motor system need of proper design and use water energy interventions. Every drop of water conserved reduces energy consumption and associated carbon emissions, although the exact amount of savings varies.

The energy intensity of different end-uses of water varies drastically with some use requiring no additional energy (e.g., irrigation, toilet flushing) and others requiring up to 203,600 kWh/ MG (e.g. dishwasher). Therefore, some water conservation measures will achieve significantly greater end-use energy savings than others. While the prospects for reducing energy through water-saving end use strategies may be quite high, national data is scarce. Some high impact solutions suitable to PMR are listed in this section.

1) Water Pumps:

Procurement should be based on efficiency not purchase price. Of a pump’s total cost over its lifetime that is 3% is for purchase and 74% is for energy. A more efficient pump also has lower maintenance and downtime costs. Typical energy saving in a total pumping system can be achieved by Size proper matching of pump size to load that is 10 to 30%, Speed variable speed drives adjust as needed 5 to 50%, System requirements don’t pump more flow and pressure than needed 5 to 20%.

2) Low Impact Development (LID):

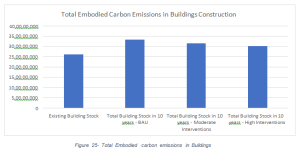

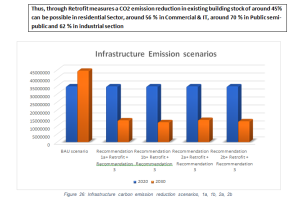

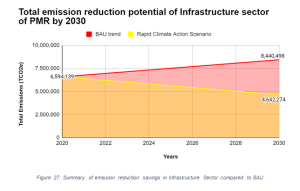

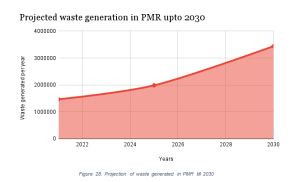

LID refers to comprehensive land planning and engineering design approaches that seek to maintain or enhance the pre-development hydrologic regime of urban and developing watersheds. In other words, LID is a stormwater management approach and set of practices that are designed to reduce runoff and pollutant loadings by managing stormwater as close to its source as possible. Green roofs, rainwater harvesting, bioretention areas (or rain gardens), permeable pavement, and riparian habitat protection are among the most commonly used LID strategies. LID strategies can reduce the energy required for stormwater treatment, avoid the carbon emissions associated with building traditional infrastructure, reduce aquifer drawdown and provide a “new” local water supply through aquifer storage or rainwater harvesting.